Winter is set to begin on December 21st, however, just a peek outside the window or a stroll down  the street tells a different story for a lot of folks around the country. Many of you are already dealing with freezing temperatures and piles of snow. So even if winter hasn’t “officially” started, we thought we would highlight a few of our previous posts that will help you and your sprayer handle the cold just a bit easier.

the street tells a different story for a lot of folks around the country. Many of you are already dealing with freezing temperatures and piles of snow. So even if winter hasn’t “officially” started, we thought we would highlight a few of our previous posts that will help you and your sprayer handle the cold just a bit easier.

Sprayer Depot Blog

Topics: Winterizing Spray Equipment, Maintenance, Boom Sprayer, Sprayer Depot, Sprayer Parts, winterize sprayer, spray tips, Sprayer Calibration, Calibrating a Boom Sprayer, sprayer tips and tricks, sprayer safety, service, calibrating app, purchasing a sprayer, things to consider

Take care of your sprayer and it will take care of you. Yes, your sprayer is a big investment and you want to make sure it's well taken care of. Proper use, care and maintenance will ensure your investment holds its value for years to come. Check out these tips from past blog posts to keep your sprayer in top shape!

Topics: Winterizing Spray Equipment, Maintenance, Boom Sprayer, Sprayer Depot, Sprayer Parts, winterize sprayer, spray tips, Sprayer Calibration, Calibrating a Boom Sprayer, sprayer tips and tricks, sprayer safety, service, calibrating app, purchasing a sprayer, things to consider

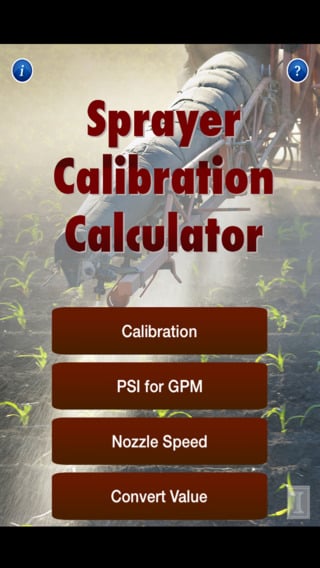

4 Features of the New Sprayer Calibration Calculator App

Posted by Sprayer Depot on Wed, Sep 17, 2014

Recently Corn and Soybean Digest reported on a newly released smartphone app called Sprayer Calibration Calculator that is designed to assist spray applicators with calibrating a pesticide sprayer. The app was developed by the University of Illinois Extension and is available free to those with Apple and Android phones. As we’ve shared in previous posts, the cost of wasted chemicals can be high when your best tool isn’t set up right.

Topics: Sprayer Depot, sprayers, pest control, Apps on the Sprayer Depot blog, Pesticide Applicators, calibrating a sprayer, pesticides, Pesticide Application Technology, Pesticide Application, Pesticide spraying, Pesticide applicator, Spray apps, apps for spraying agriculture, pest control app, Sprayer Calibration, sprayer checklist, Sprayer Set Up, Calibrating a Boom Sprayer, Boom Sprayer Calibration, sprayer tips and tricks, University of Illinois, Scott Bretthauer

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)