Contributed by Guest Blogger:

Mark Techler, Factory Representative - Hypro & SHURflo Ag and Industrial Pumps and Accessories

Sprayer Depot Blog

Guest Post: How Centrifugal Pumps Are Different From Diaphragm Pumps

Posted by Sprayer Depot on Wed, Jun 08, 2016

Topics: Hypro, Diaphragm pumps, sprayer, Centrifugal Pump, Transfer Pumps, Guest blog

You’re on the market for a new spray pump. You have a pretty clear idea of what you need. After all, nine times out of ten it’s a replacement pump that’s on its last leg and in need of replacing. Not an easy pill to swallow when you have to buy one of the most vital parts for your sprayer. But where do you start?

Topics: Spray Equipment Maintenance, Hypro, Udor, Diaphragm pumps, Sprayer Depot, Sprayer Parts, diaphragm pump, Diapgragm pumps, sprayer, Centrifugal Pump, Roller Pump, centrifugal pumps, roller pumps, sprayer pumps, Udor Pumps, Transfer Pumps, Hypro Pump, Sprayer Pump, Roller Pump Repair, spray pumps, centrifrugal pump, Shurflo, sprayer equipment, parts, Comet Pumps, Triple Diaphragm Pumps, Pump, sprayer tips and tricks, customer service, Banjo, Myers, Myers Pumps, Banjo pumps, SHURflo pumps, buyer beware, price match, best price, lowest price

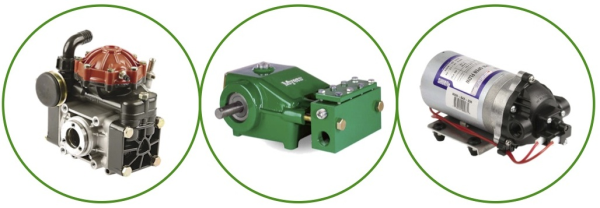

We are halfway through spray season and you know what that means, time for routine maintenance to keep your sprayers working like a well-oiled machine. Most manufacturers recommend this regular upkeep every three months, with more attention needed during this heavy use time of year. Here we’ll cover three sprayer pump types – diaphragm, centrifugal and roller – and provide the information you need to know to ensure smooth operation for the remainder of the season.

Topics: diaphragm pump, Pump Repair, Centrifugal Pump, Roller Pump, pump repair kit, o-rings

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)