Today we’ll talk about that dreaded term — spray drift. It’s one of the basic principals of spraying that spray applicators do their best to control and there are a number of factors to consider. The type of spray drift we’re talking about is when an application like pesticides misses its intended target. It makes the task at hand a bit more complicated. You need to factor in wind, droplet size, height, materials used, and so much more.

Read MoreSprayer Depot Blog

Topics: sprayers, pest control, spray tips, Pesticide Application Technology, Pesticide Application, spray tip selection, spray drift, spray tip selector, drift control spray tip, drift control

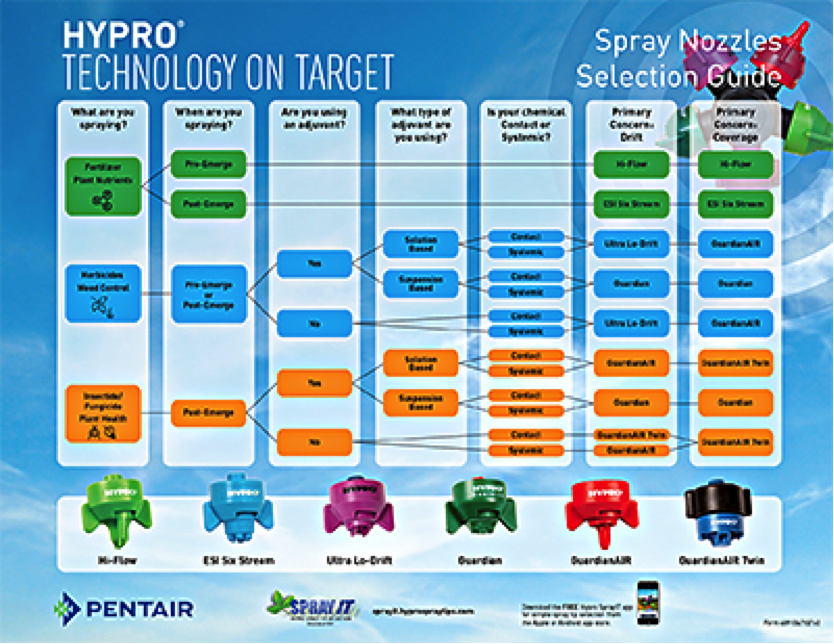

We’re always looking for ways to make spray nozzle selection easier and we’ve shared some tips of the trade in past posts right here on our blog. With new advances in technology and an ever-evolving line-up of options, we couldn’t resist sharing this Spray Nozzle Selection Guide and helpful information from our friends at Hypro.

Topics: Hypro, herbicides, Sprayer Depot, Sprayer Parts, pest control, spray tips, Spray Nozzles, pesticides, Pesticide Application, Pesticide applicator, spray tip, spray tip selection, Sprayer Parts Guide, spray smarter, sprayer nozzle, tip selector, tip selection, spray tip selector, fungicides, Sprayer Nozzles, spray nozzle, weed control, fertilizer, insecticide, plant health, spray tip guide, nozzle selection guide, spray nozzle selection

As the season changes to autumn (officially on Sept. 22, 2014), the scenery for many of us quickly follows, adding to it shades of red, orange and yellow to the typically green landscape. The weather too will turn cooler (at least we’re hopeful in Florida) and of course the needs of our sprayer changes too. While we’re not quite to the point where we need to winterize our tools, care should be given to prep for that necessary activity and to ensure the changing weather elements don’t impact the end of your season. We’ve combed over our collection of trade tips to uncover the essential needs for this time of year.

Topics: Spray Equipment Maintenance, Winterizing Spray Equipment, lawn sprayer, diaphragm pump, spray equipment checklist, sprayer performance, sprayer strainer, Pesticide Application, spray nozzle, valves, parts, sprayer tips and tricks

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)