This information on how to repair a Hypro roller pump is provided courtesy of Hypro. For more detailed information on the repair procedures for Hypro Roller Pumps, call a Sprayer Depot Customer Service Technician at 800-228-0905.

Read MoreSprayer Depot Blog

Topics: Hypro Roller Pump Repair Kit, Roller Pump, Hypro Pump

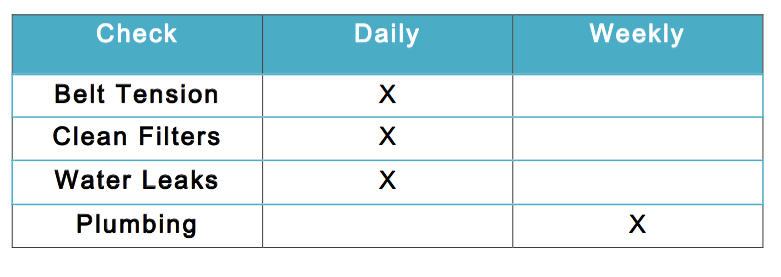

Your pump will last longer and perform at its best if you keep up with routine service. How often should you maintain your pump will depend on how often you use it and the type of liquid being pumped. However, there are general guidelines that the manufacturer recommends should be followed to properly maintain your pump.

Hypro Roller Pumps are some of our most popular pumps. They are used across different industries such as pest control, weed control, horticulture and other agricultural applications.

Topics: Spray Equipment Maintenance, Sprayer Depot, winterize sprayer, Roller Pump, sprayer pumps, Hypro Pump, Hypro Roller Pump, Sprayer Pump, Sprayer Parts Guide

Guest Post: Comparison of Roller to Diaphragm Pumps for Horticultural Spraying

Posted by Sprayer Depot on Thu, Oct 08, 2015

Contributed by Guest Blogger:

Mark Techler, Factory Representative - Hypro & SHURflo Ag and Industrial Pumps and Accessories

Topics: Hypro, Diaphragm pumps, sprayer, Roller Pump, spray tips, spray nozzle, horticulture, Guest blog

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)