As the summer season draws to a close and we start to think about preparing our equipment for the winter season, our to-do list grows long. Thank you notes to clients, winterizing all equipment, and finding storage for supplies and back up supplies, are all on the agenda for fall. The tasks can easily begin to seem overwhelming.

Read MoreSprayer Depot Blog

Topics: Winterizing Spray Equipment, spray nozzle, Teejet, Hypro spray tips

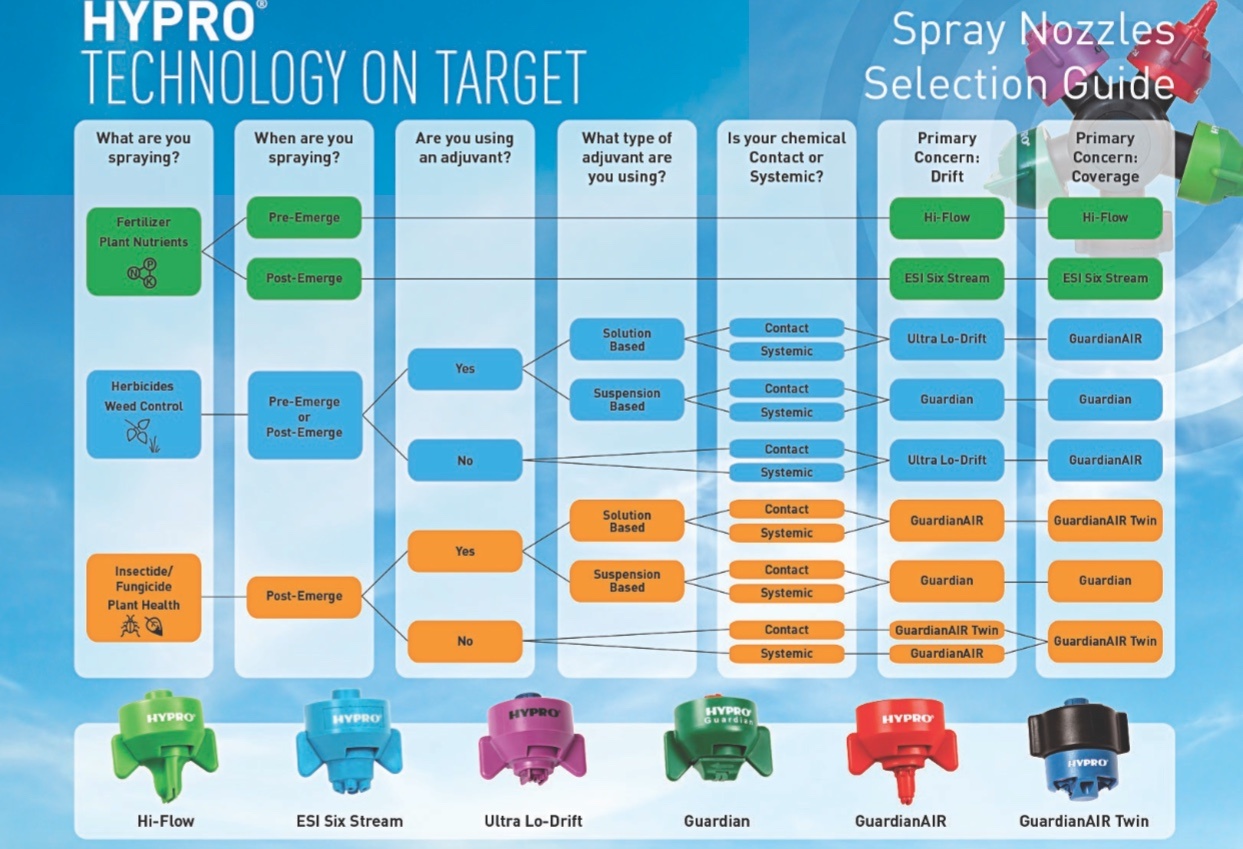

Nozzles may be small, but they play a critical role in the application of chemicals. Selecting the proper size and type of nozzle is an essential step to determine the amount of spray applied to an area. Use the wrong nozzle, and you may over or under spray the solution which will result in an ineffective application.

A few questions that will help you make the best nozzle selection for your particular application include:

1. What's your application type? (i.e., agricultural, pest control, lawn & landscape, etc.)

2. What's the predetermined distribution pattern? (i.e., broadcast, banded, stream, etc.)

3. What's the recommended droplet size?

4. What type of nozzle material is needed to avoid corrosion?

Let's go over a couple of key elements you can apply to answer the questions above:

Topics: Hypro, Sprayer Parts, pest control, spray tips, Spray Nozzles, spray nozzle, spray tip guide, nozzle selection guide, spray nozzle selection, Teejet

Guest Post: Comparison of Roller to Diaphragm Pumps for Horticultural Spraying

Posted by Sprayer Depot on Thu, Oct 08, 2015

Contributed by Guest Blogger:

Mark Techler, Factory Representative - Hypro & SHURflo Ag and Industrial Pumps and Accessories

Topics: Hypro, Diaphragm pumps, sprayer, Roller Pump, spray tips, spray nozzle, horticulture, Guest blog

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)