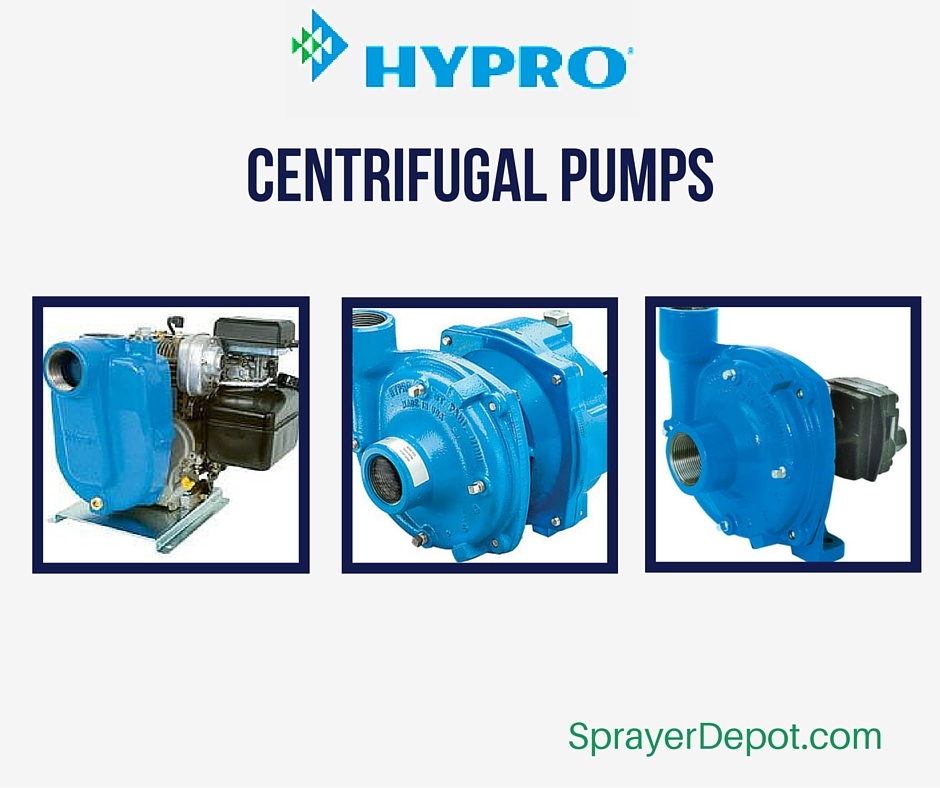

Centrifugal pumps are high flow, low-pressure pumps that can deliver pressure ratings of anywhere from 0 to 150 psi and flow rates up to 440 gpm. How exactly do centrifugal pumps work? Well, if you are feeling a bit technical, here’s a simple explanation: On a centrifugal pump, the liquid enters through the middle into an impeller that forces the liquid into the outlet of the pump.

Centrifugal pumps are known to be heavy-duty and durable due to their fewer parts and minimum wear surfaces. Another great feature is they are easy to clean and maintain.

They can be used in a variety of applications including agricultural and industrial spraying. They come in different materials such as cast iron, stainless steel, and even polypropylene, making them capable of handling a variety of liquids and chemicals. They are mostly used with water, insecticides, herbicides, wettable powders, emulsives, and liquid fertilizers just to name a few. Some centrifugal pumps, specifically those made from polypropylene, can handle acids and other corrosive liquids.

Centrifugal pumps can be powered by different methods, the most common include:

Tractor/PTO

Series 9000 - 9400 Belt-Driven Centrifugal Pumps

This series is specifically designed for easy use with tractor mounted sprayers. They can handle big, high-capacity spraying jobs with ease and are easy to install/uninstall.

Pressure ratings: 62 - 104 psi

Flow rate: 82 - 140 gpm

Speed: 600 or 1000 rpm

Gas Engine

Series 1500 Gas Engine-Driven Centrifugal Pumps

As their name describes, this series can be mounted onto a gas engine. They are available with or without a mounting base for easy and secure installation depending on your engine. Need a pump that can tackle more than just spraying? Fill tanks, water seed beds and transfer liquids fast and efficiently with Hypro’s centrifugal pumps.

Pressure ratings: 65 - 140 psi

Flow rate: 98 - 150 gpm

Speed:

Hydraulic Motor

Series 9300 Hydraulically-Driven Centrifugal Pumps

Hypro Hydraulically-driven pumps are capable of achieving high speeds while providing smooth performance. One of their advantages is that they can be easily mounted on a tractor or sprayer. Another great feature is Hypro's "close-coupled" design which saves space on your set-up by

Pressure ratings: 120 - 180 psi

Flow rate: 100 - 214 gpm

Hydraulic ports: 1/2" NPT inlet, 3/4" NPT tank

There are a lot of other options when it comes to spray pumps, each better-suited for a variety of applications. Stay tuned for future posts on how to service and troubleshoot your Hypro centrifugal pump, so don't forget to subscribe to our blog.

If you need help choosing the ideal pump for the job, or if you have questions that we didn't cover, leave your questions in the comment box below. If you'd like to talk to someone directly, contact our helpful Customer Service Technicians today!

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)