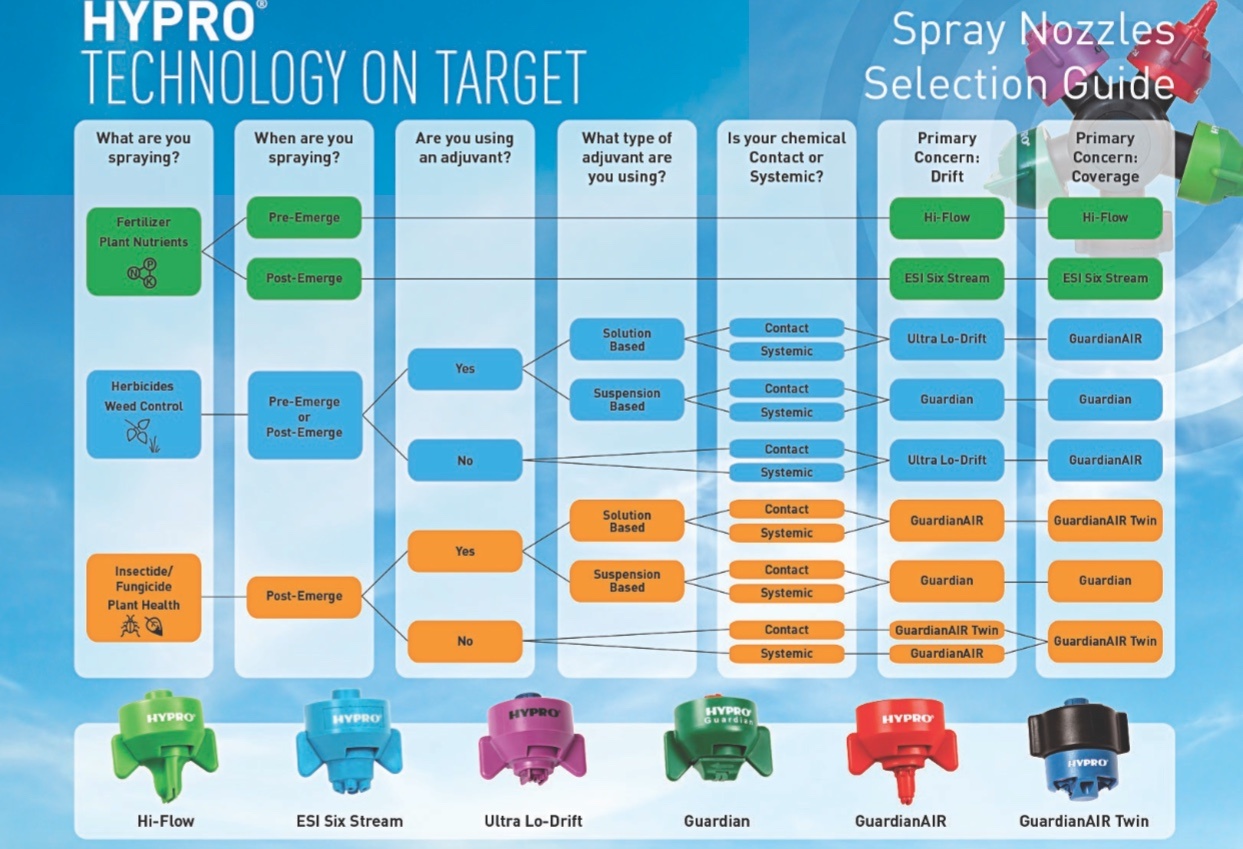

Nozzles may be small, but they play a critical role in the application of chemicals. Selecting the proper size and type of nozzle is an essential step to determine the amount of spray applied to an area. Use the wrong nozzle, and you may over or under spray the solution which will result in an ineffective application.

A few questions that will help you make the best nozzle selection for your particular application include:

1. What's your application type? (i.e., agricultural, pest control, lawn & landscape, etc.)

2. What's the predetermined distribution pattern? (i.e., broadcast, banded, stream, etc.)

3. What's the recommended droplet size?

4. What type of nozzle material is needed to avoid corrosion?

Let's go over a couple of key elements you can apply to answer the questions above:

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)