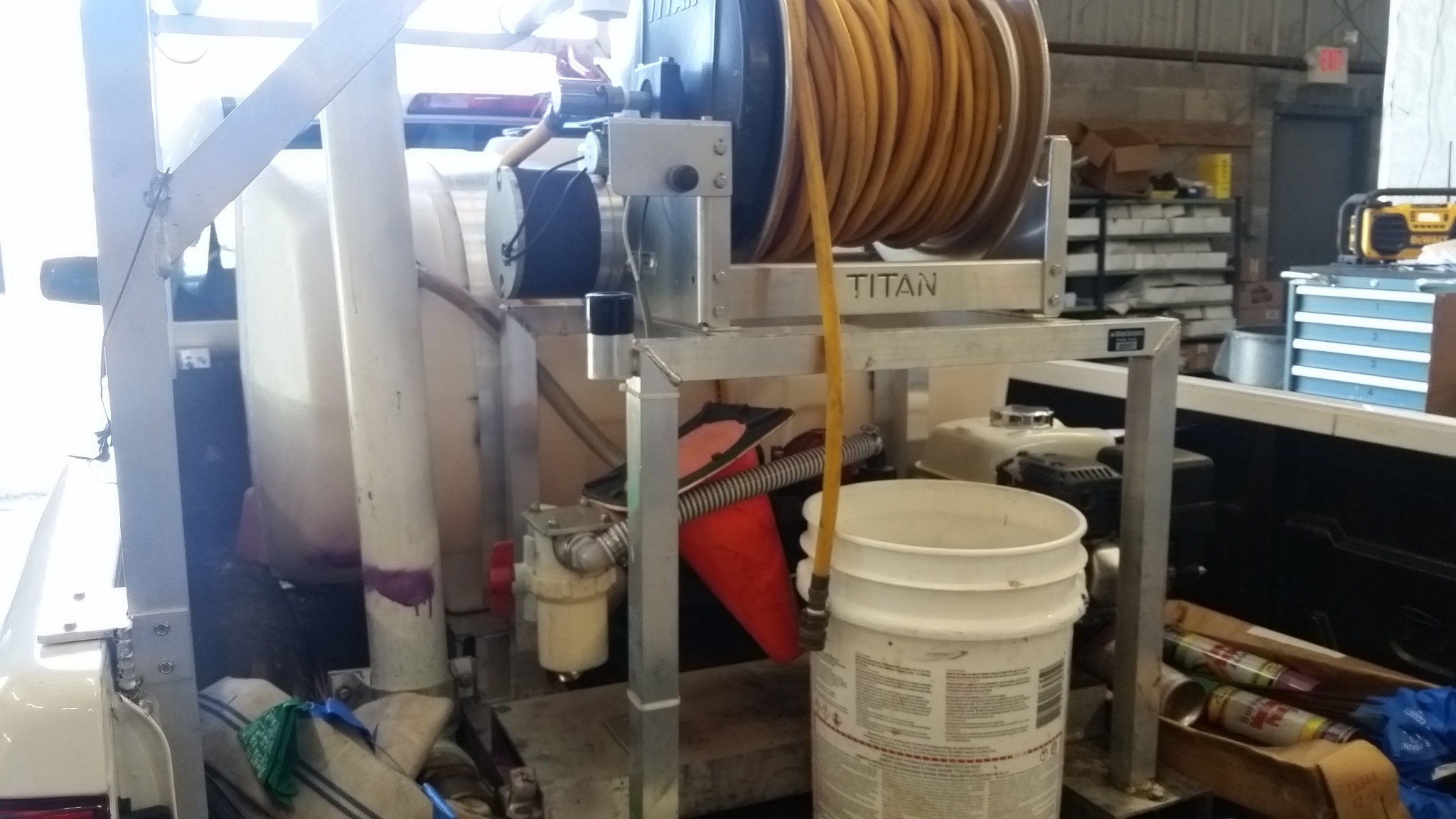

During the busy summer season, it's easy to overlook spray equipment maintenance. However, to keep your equipment running smoothly all year round, it's a good idea to run through this quick summer maintenance checklist.

Read MoreSprayer Depot Blog

Topics: Sprayer Pump, Sprayer Pump Repair, sprayer maintenance

That chill that you’re feeling in the air means a number of different things: winter is in full force, it’s time to plan your Super Bowl party, and your business may be smack dab in the middle of its slow season (or at least shifting to another seasonal service). That likely means less use for your spray equipment. Yet before you go covering it with a tarp, ask yourself this question: Have I properly winterized the system to avoid unnecessary equipment repairs in the spring?

Why Winterize?

Why not just store your spray equipment away after your last application and forget about it until spring comes around again? Well, the longer your spray equipment is left inactive, the greater potential there is for it to fail. Any chemicals or residue left in the system can saturate into soft components such as hoses and valves, weakening them to the point of not functioning properly when you first start your sprayer back up again. Plus, having leftover residue in the system increases the chances of cross-contamination if you use your sprayer for multiple purposes.

Read MoreTopics: Winterizing Spray Equipment, sprayers, sprayer maintenance

Maximize Efficiency: Perform a Mid-Season Spray Equipment Check-Up

Posted by Sprayer Depot on Fri, Jun 24, 2016

You have been working hard and your spray equipment has already logged many hours

in the field. However, in many parts of the country, busy season has yet to peak. In the crunch of meeting customer demand, it can be easy to place equipment maintenance on the back burner, but this is the one task you can't afford to miss.

Topics: Spray Equipment Maintenance, Sprayer Calibration, sprayer maintenance

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)