It’s always a good idea to review the manufacturer information when starting your skid sprayer for the first time. For the Kings Sprayers line we offer quick set up information in a variety of ways, through our website, YouTube videos and Customer Service Technicians. After all, many of our customers have tackled these steps many times over. However, as technology changes and sprayers are more and more customized, it’s always a good idea to take a second glance at the getting started information.

Sprayer Depot Blog

Quick Set Up for a Kings Sprayer 50 Gallon Utility Skid Sprayer

Posted by Sprayer Depot on Wed, Oct 08, 2014

Topics: Custom-built Skid Sprayer, Spray Guns, Sprayer Depot, Kings Sprayers, Quickship Sprayers, Skid Sprayers, spray tips, Sprayer Depot Instructional Video, sprayer checklist, Sprayer Set Up, utility skid sprayer, how to operate a skid sprayer, quick set up skid sprayer, skid sprayer quick start

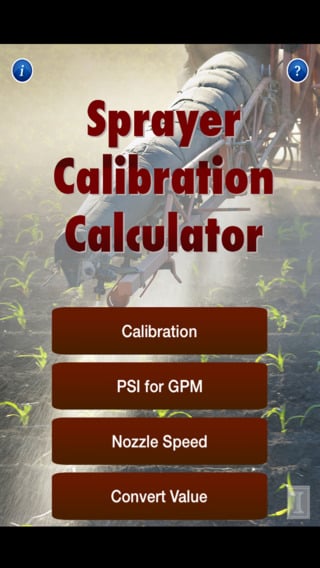

4 Features of the New Sprayer Calibration Calculator App

Posted by Sprayer Depot on Wed, Sep 17, 2014

Recently Corn and Soybean Digest reported on a newly released smartphone app called Sprayer Calibration Calculator that is designed to assist spray applicators with calibrating a pesticide sprayer. The app was developed by the University of Illinois Extension and is available free to those with Apple and Android phones. As we’ve shared in previous posts, the cost of wasted chemicals can be high when your best tool isn’t set up right.

Topics: Sprayer Depot, sprayers, pest control, Apps on the Sprayer Depot blog, Pesticide Applicators, calibrating a sprayer, pesticides, Pesticide Application Technology, Pesticide Application, Pesticide spraying, Pesticide applicator, Spray apps, apps for spraying agriculture, pest control app, Sprayer Calibration, sprayer checklist, Sprayer Set Up, Calibrating a Boom Sprayer, Boom Sprayer Calibration, sprayer tips and tricks, University of Illinois, Scott Bretthauer

When we say we know sprayers, it’s true. Our team builds more than 500 custom sprayers each year for customers looking to modify or completely reconfigure the makeup of this important tool. After all, you don’t have to settle for less than perfect in the sprayer world. Just turn to our Sprayer Depot knowledgeable customer service technicians with your ideas and < bam > the perfect custom sprayer is born. Here we’ll take a look at some of the common modifications to a few of our best selling sprayer models from Kings Sprayers.

Topics: Kings Sprayer, Spray Equipment Maintenance, Hoses, Custom-built Skid Sprayer, Hose Reel, Hose Reels, Custom-built sprayer, Custom-build a sprayer, Spray Guns, Sprayer Depot, custom built sprayers, custom build sprayer, Customer, Sprayer Parts, sprayers, sprayer performance, Kings Sprayers, Skid Sprayer, sprayer pumps, Sprayer Pump, Skid Sprayers, Spray Hose, spray pumps, Sprayer Parts Guide, Kings Skid Sprayer, spot sprayers, sprayer equipment, sprayer tanks, Sprayer Set Up, parts, Kings Spot Sprayers, customer service

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)