Summer is the busiest time of year for many of our customers. It's the height of the spray season which means the team here at Sprayer Depot is hard at work to make sure our customers get what they need.

Read MoreSprayer Depot Blog

Topics: Diapgragm pumps, JD9 Spray Gun, Hypro D30 Pump, Greensmaster Spray Gun, high pressure spray hose

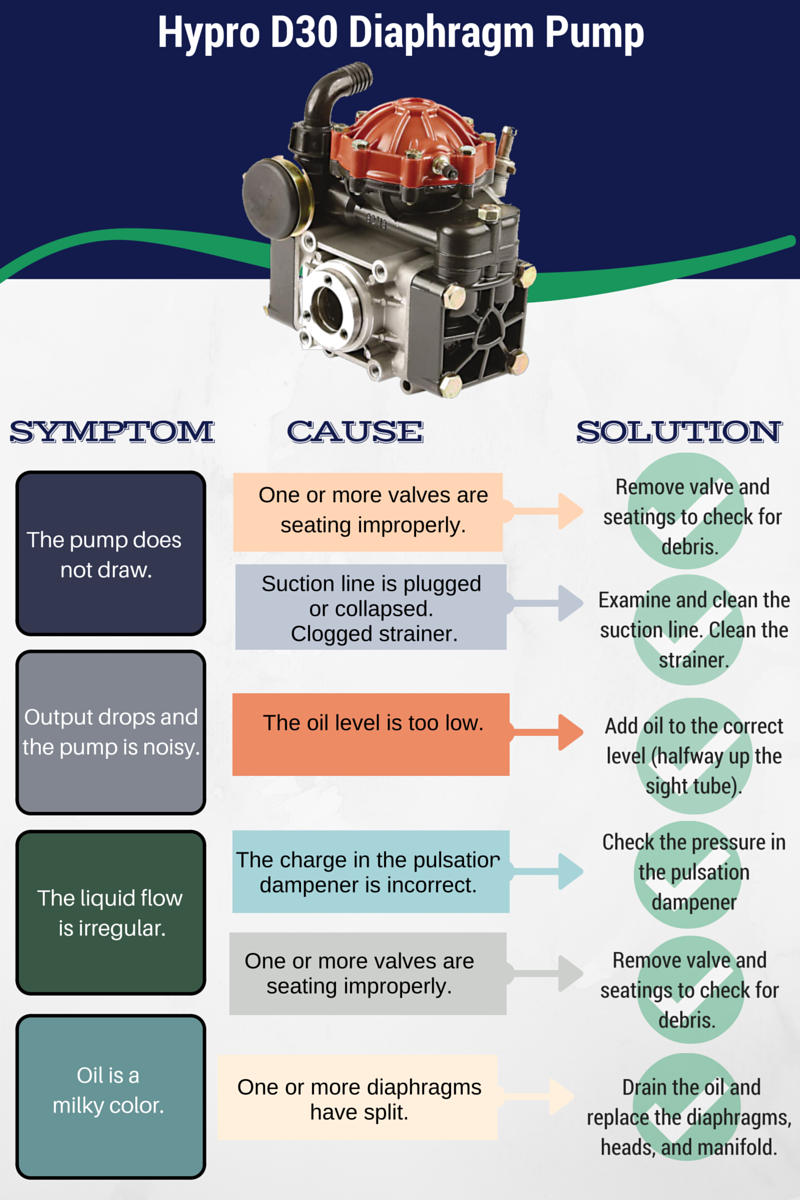

Troubleshooting the Hypro D30 Diaphragm Pump: An Update on a Popular Topic

Posted by Sprayer Depot on Fri, Jun 30, 2017

We receive many calls and emails from customers requesting help troubleshooting the Hypro D30 diaphragm pump. In this post, we've updated some information previously published on this topic to highlight some easy-to-identify solutions.

Read MoreTopics: Hypro, diaphragm pump, Hypro D30 Pump, infographics

It's officially summer, and that means it's the time of year many of us are working at full capacity to maximize the business opportunities of the season. A little planning can go a long way, though. Making sure that equipment is running properly means making sure your equipment is in full operational condition and having spare parts on hand, just in case of a break-down and things don't go according to plan.

Read MoreTopics: JD9 Spray Gun, JD9 Spray Gun Repair, Hypro D30 Pump, commercial spray equipment

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)