Proper Sprayer Maintenance Requires Keeping the Right Sprayer Parts in Inventory

"How many spare parts should I keep on hand?" This question seems to come up often. While some customers like to stay prepared by keeping extra pumps, engines and other major sprayer components on hand, most keep a few key sprayer parts on the their shelves in order to do quick repairs in the field. Here are the top 3 "must-have” parts that we recommend to keep on hand:

Read More

Topics:

Sprayer Parts,

sprayer nozzle,

agitator,

tank basket filter

Spray tips are important, but these small components happen to be an often-overlooked part of a sprayer. With so many options on the market it’s no wonder that you might feel overwhelmed with choices. However, the benefits of finding the right tip for your application will pay in spades in the long run. Determining which spray nozzle is best for your needs depends on a variety of factors, including the type of spray application and your sprayer equipment.

Read More

Topics:

spray tips,

Spray Nozzles,

spray tip,

spray tip selection,

sprayer nozzle,

spray tip calculator,

spray tip selector,

drift control spray tip,

Sprayer Nozzles,

spray nozzle,

spray tip guide,

nozzle selection guide,

spray nozzle selection

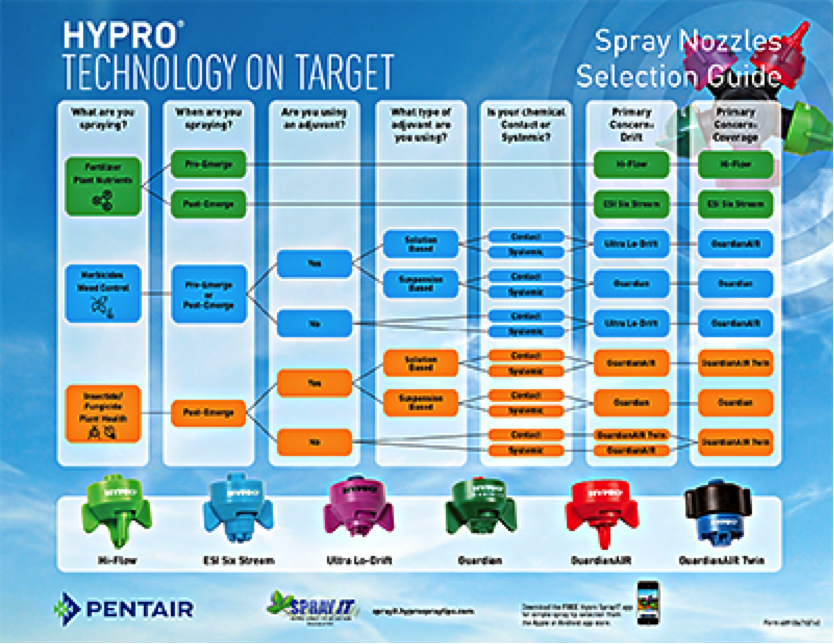

We’re always looking for ways to make spray nozzle selection easier and we’ve shared some tips of the trade in past posts right here on our blog. With new advances in technology and an ever-evolving line-up of options, we couldn’t resist sharing this Spray Nozzle Selection Guide and helpful information from our friends at Hypro.

Read More

Topics:

Hypro,

herbicides,

Sprayer Depot,

Sprayer Parts,

pest control,

spray tips,

Spray Nozzles,

pesticides,

Pesticide Application,

Pesticide applicator,

spray tip,

spray tip selection,

Sprayer Parts Guide,

spray smarter,

sprayer nozzle,

tip selector,

tip selection,

spray tip selector,

fungicides,

Sprayer Nozzles,

spray nozzle,

weed control,

fertilizer,

insecticide,

plant health,

spray tip guide,

nozzle selection guide,

spray nozzle selection

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)