They may be small but they happen to be one of the most critical (and easy to replace) component of your spray equipment and should definitely not be underestimated! Spray nozzles, like any other part of your spray equipment inventory, should be routinely checked for problems or issues that could impact the delivery of your fluids. For optimum efficacy and trouble free applications take a moment to inspect your spray nozzles-it's a simple task but could save you time and money at the end of the day!

Read MoreSprayer Depot Blog

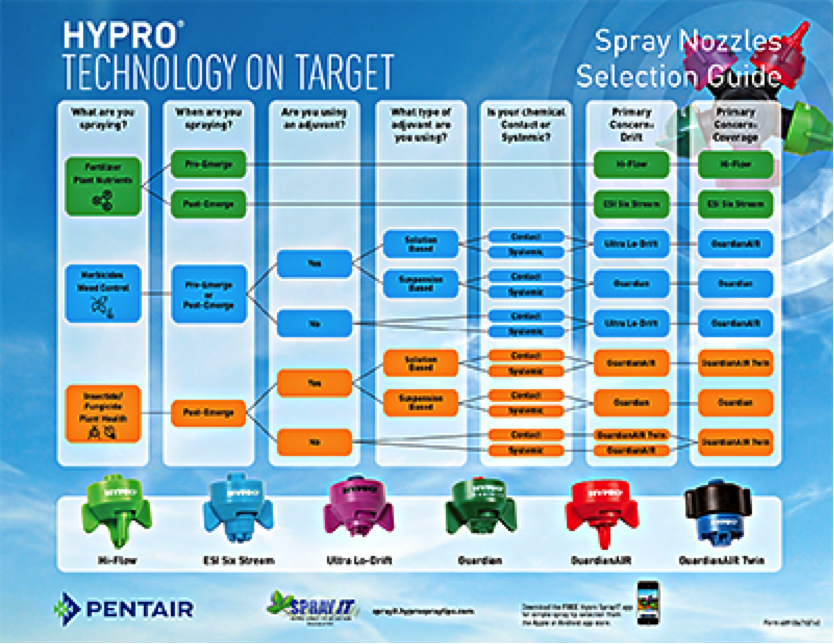

Spray tips are important, but these small components happen to be an often-overlooked part of a sprayer. With so many options on the market it’s no wonder that you might feel overwhelmed with choices. However, the benefits of finding the right tip for your application will pay in spades in the long run. Determining which spray nozzle is best for your needs depends on a variety of factors, including the type of spray application and your sprayer equipment.

Read MoreTopics: spray tips, Spray Nozzles, spray tip, spray tip selection, sprayer nozzle, spray tip calculator, spray tip selector, drift control spray tip, Sprayer Nozzles, spray nozzle, spray tip guide, nozzle selection guide, spray nozzle selection

We’re always looking for ways to make spray nozzle selection easier and we’ve shared some tips of the trade in past posts right here on our blog. With new advances in technology and an ever-evolving line-up of options, we couldn’t resist sharing this Spray Nozzle Selection Guide and helpful information from our friends at Hypro.

Topics: Hypro, herbicides, Sprayer Depot, Sprayer Parts, pest control, spray tips, Spray Nozzles, pesticides, Pesticide Application, Pesticide applicator, spray tip, spray tip selection, Sprayer Parts Guide, spray smarter, sprayer nozzle, tip selector, tip selection, spray tip selector, fungicides, Sprayer Nozzles, spray nozzle, weed control, fertilizer, insecticide, plant health, spray tip guide, nozzle selection guide, spray nozzle selection

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)