Contributed by guest blogger: Mark Techler, Techler & Associates

Obtain optimal sprayer performance with a diaphragm pump and hose reel by following these guidelines:

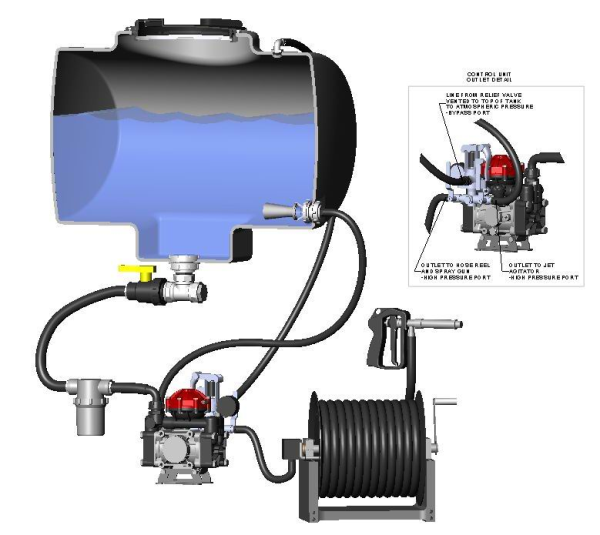

To ensure proper hook-up of diaghragm pump and hose reel, see diagram below

- Place the outlet fitting in the lowest point in the tank, or in the sump

- Connect a ball valve to the outlet tee (or elbow) so you can turn off the flow in case you need to service the pump or check the line strainer

- Include a line strainer between the tank and the pump to prevent debris from clogging the pump, relief valve, gun and nozzle

- The tank outlet fitting, elbow, suction line and strainer should be one pipe size larger than the suction port of the pump; The suction line should be reinforced so it does not collapse, but remains flexible so it absorbs pulsation (A clear suction line helps you see air bubbles if there is is air entering the system)

- Even though diaphragm pumps prime well, try to posititon the pump lower than the tank for gravity feed

- Most diaghragm pumps include a "control unit" consisting of a relief valve, multiple discharge ports with ball valves, and a pressure gauge (It can be mounted on the pump or remote mounted - If a remote mount is used, do not put a shutoff valve between the pump and the control unit)

- Connect the relief valve bypass port with an unrestricted line to the top of the tank, venting to atmospheric pressure - DO NOT PUT A SHUTOFF VALVE IN THIS LINE OR CONNECT THE BYPASS LINE TO THE AGITATOR - Restrictions may prevent the relief valve from bypassing properly and may result in damage to the pump

- Connect one of the discharge lines to the agitator(s); It's okay to use a ball valve in this ine to throttle the flow

- Connect one of the discharge lines to the inlet swivel on the hose reel; It's okay to use a ball valve in this line; Do not use hard plumbing when connecting the discharge line to the hose reel swivel

- Connect the spray gun

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)