Here at Sprayer Depot we know that farmers, pest control companies, landscaping contractors and golf courses all over the world need sprayer parts and accessories and that is why we offer international shipping! With affordable international shipping you get your professional spray equipment, and can get back to work anywhere in the world and save money too.

Read MoreSprayer Depot Blog

Marketing Manager

Recent Posts

Topics: Hose Reel, spray equipment, Boom Sprayer, Spray Guns, Sprayer Depot, Sprayer Parts, sprayers, spray equipment checklist, Skid Sprayer, sprayer pumps

Topics: Spray Equipment Maintenance, sprayer, Centrifugal Pump, Roller Pump, centrifugal pumps, roller pumps, sprayer pumps

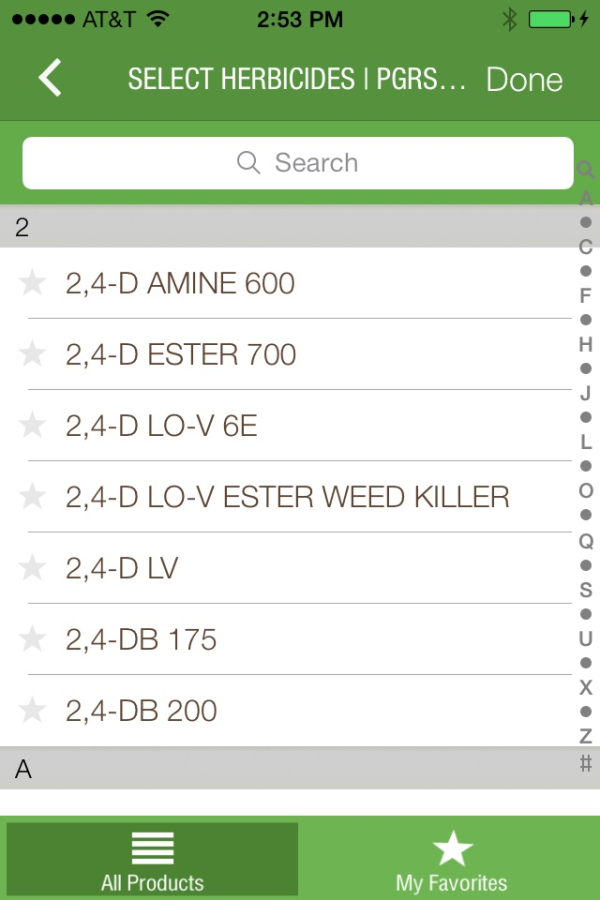

Spraying for pest control, agriculture or lawn and landscape maintenance requires precision and planning. Today there are apps that can help spray applicators with everything from figuring out the right tank mixing sequences to capturing product usage rates. Compatible with both iPhone and Android devices, these apps simplify planning while increasing control for the professional spray applicator.

Topics: Spray apps, MixTank, apps for spraying agriculture, pest control app

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)