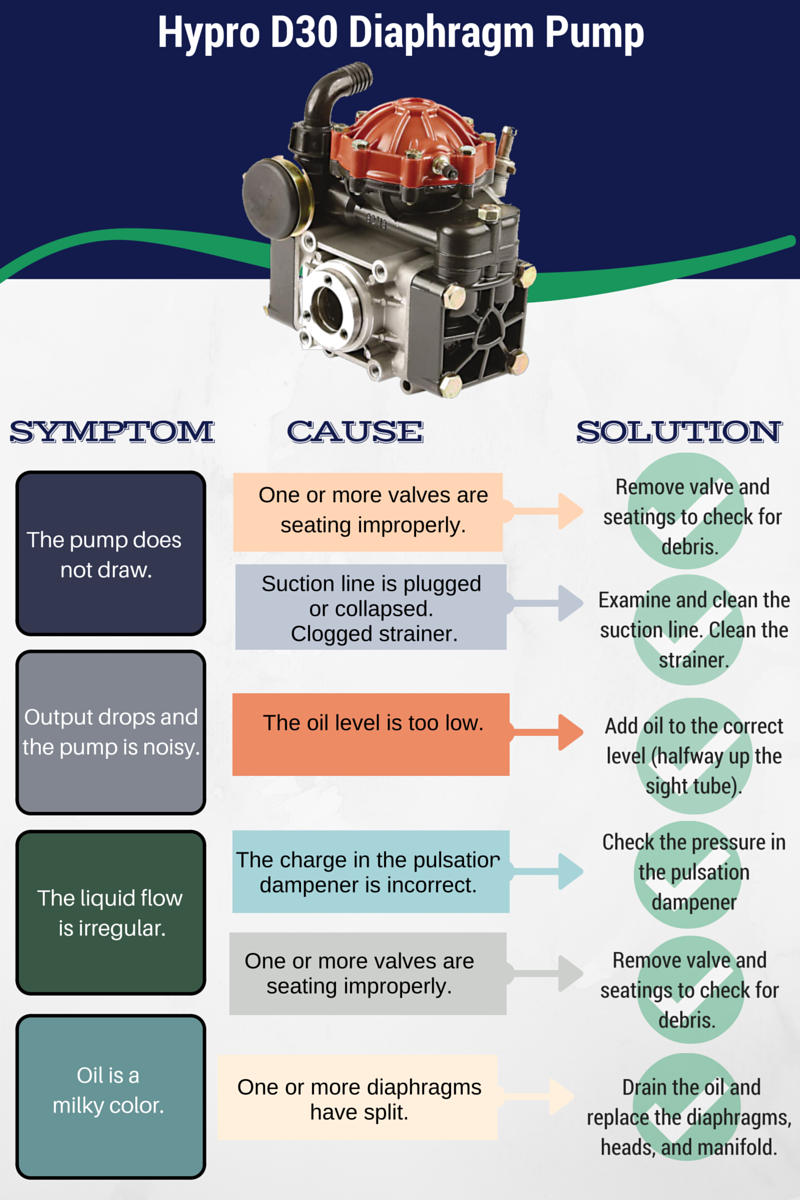

We receive many calls and emails from customers requesting help troubleshooting the Hypro D30 diaphragm pump. In this post, we've updated some information previously published on this topic to highlight some easy-to-identify solutions.

Read MoreSprayer Depot Blog

Troubleshooting the Hypro D30 Diaphragm Pump: An Update on a Popular Topic

Posted by Sprayer Depot on Fri, Jun 30, 2017

Topics: Hypro, diaphragm pump, Hypro D30 Pump, infographics

Sprayer Depot recently introduced a new video series called “Tuesday Spray Tips”, specifically designed to share spray equipment information in 30 seconds or less, twice a month. We are so excited about the response to the new videos, we are tipping our hats off to each and every one of our customers who has watched, shared, liked and commented on the videos. Thanks for your support!

Just in case you’ve missed them, we will share a brief recap every month where you’ll have the opportunity to get caught up and watch the videos. (Or just watch them all over again!)

Let’s take a look at May’s Tuesday Spray Tips videos:

We started off with a short video showcasing one of our recent custom-built sprayers. The Kings Sprayers 200 Gallon Hot Water Pressure Washer Sprayer features a hot water heater making it great for sanitizing and debris removal. It can be used in truck beds, utility vehicles, boats, and trailers. There is no clean up job too difficult for this sprayer! Check it out:

Read More

Topics: Spray Equipment Maintenance, Sprayer Depot, diaphragm pump, spray tips, hot pressure washer sprayer, clearance, Tuesday Spray Tips

We previously asked you to cast a vote on new instructional video topics for our YouTube Channel. We wanted to know more about the topics that interest you the most, and what types of videos you want to see on our social media channels. We appreciate the feedback and love when customers tell us exactly what they want. The votes are in, and it looks like we have a winner: Repair Videos!

Here’s a quick breakdown of the results:

We already offer a wide selection of repair videos on our website and YouTube channel, and are happy to learn you crave even more of this type of content! We are in the process of designing comprehensive instructional videos that will teach you how to repair and operate some of the most commonly used spray equipment in the industry such as diaphragm pumps, spray guns and strainers, just to mention a few.

Read MoreTopics: Sprayer Depot, diaphragm pump, Instructional Video, Hypro Pump, Youtube

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)