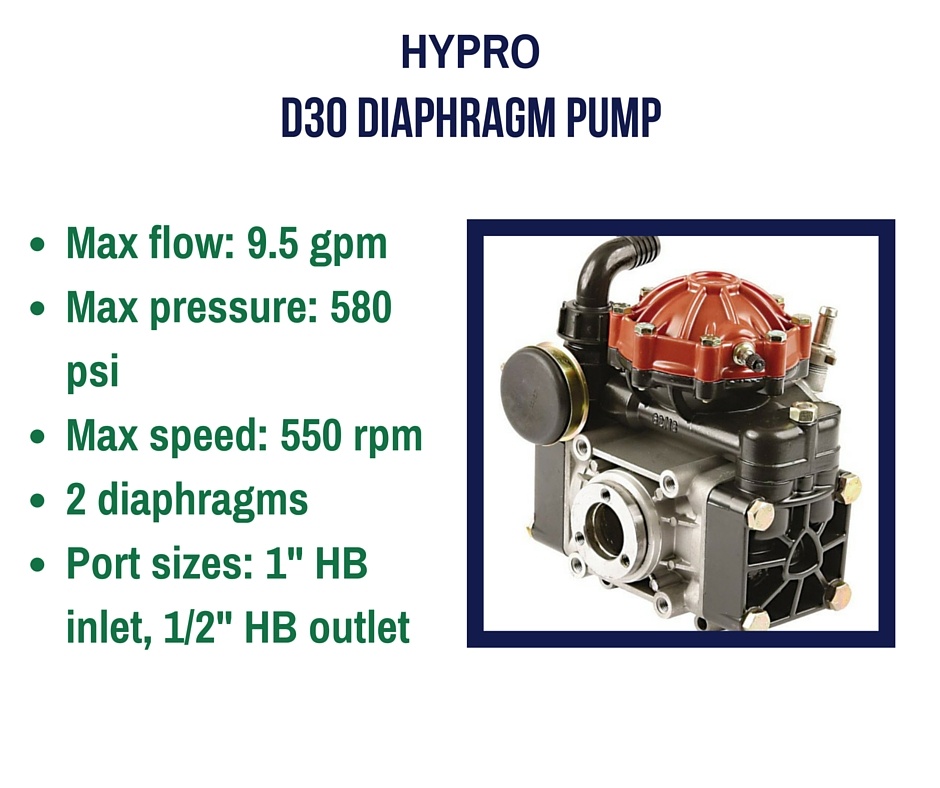

Hypro diaphragm pumps are recommended for spraying herbicides, pesticides, liquid fertilizers, and many other hard-to-handle fluids. The Hypro D30 is one of Hypro's most popular medium pressure diaphragm pumps. Its low cost maintenance, and almost wear-free operation help make it the ideal choice for a wide variety of spraying jobs. This is definitely one of our top selling pumps, and the preferred choice for several of our small to medium-sized Kings Sprayers® models.

Interested in learning more? Let's look at the specs on this pump!

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)

sharing our

sharing our