Spray equipment failure can be quite expensive if you are caught unprepared. We recommend always having spare parts on hand to keep you going when unplanned downtime happens. However, even with all the right spare parts in your sprayer emergency kit, sometimes you can’t anticipate what will break and if you will be able to repair it quickly. Maximize your uptime by having a service and repair plan established. Know where you can take your spray equipment for fast service and quality repairs before something happens.

Read MoreSprayer Depot Blog

Topics: Sprayer Depot, Sprayer Depot Instructional Video, customer service, customer service technician, repair, showroom, service

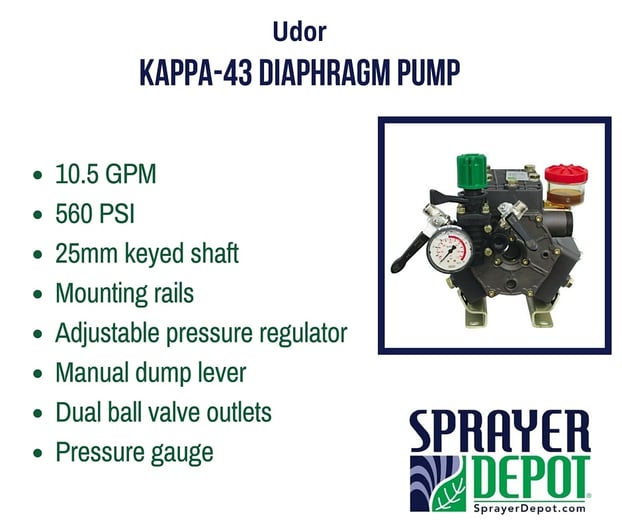

Udor Kappa series pumps offer reliable, high-quality and popular solutions when working with harsh chemicals. Due to their anodized aluminum construction, they are ideal for handling a number of common of professional chemicals, such as herbicides, pesticides, liquid fertilizers, de-icing materials, and other hard-to-handle fluids.

One of our top sellers is the Udor Kappa-43 diaphragm pump. This is a commonly used pump in various horticulture, agricultural, lawn care, nursery, pest control and turf spraying applications. Let's take a closer look at some of its best features!

Probably the most common issue we see with this type of pump is a diaphragm rupture. Fortunately, this is a pretty easy repair you can do yourself to save time and money. Continue reading below for steps on how to repair a Udor Kappa-43 Diaphragm pump and watch the easy instructional video that follows.

For this project you will need the following tools:

- A screwdriver

- Wrench

- 1/2" socket

- 11/16" socket

- Diaphragm kit (3 piston diaphragms, 6 sets of O-rings)

Let's get started! Follow these steps:

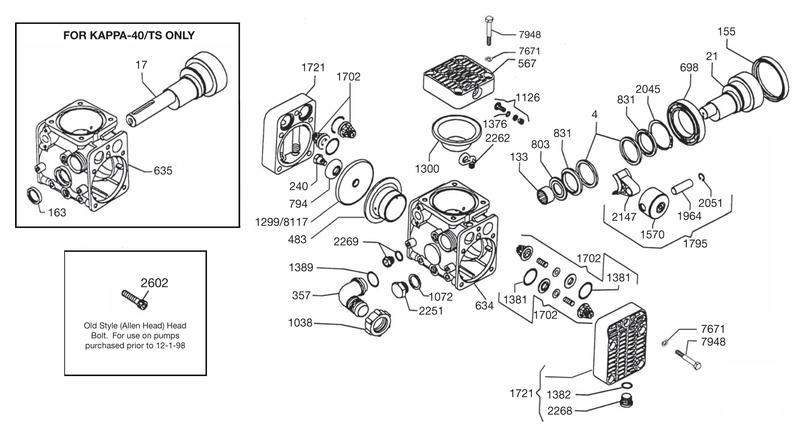

- Loosen the bolts on one of the 3 head assemblies

- Remove the head assembly

- Remove the diaphragm, nut, and washer

- Remove the diaphragm

- Remove the sleeve, and drain the internal oil

- Loosen the bolts on the 2nd head assembly

- Remove the head assembly

- Remove the diaphragm, nut, and washer

- Remove the diaphragm

- Remove the diaphragm sleeve

- Repeat this process on the remaining head

- Clean the inside of the pump with carb or brake cleaner

- Replace the sleeve, lining up the holes on the sleeve with the holes on the piston

- The diaphragm has a beveled side; this side will be pointing out

- Replace the diaphragm, nut, and washer; tighten with a wrench

- On each side of the 3 outer head assemblies remove the inside of the valve cage, replace the spring, small seat (beveled side down), and large metal seat

- Place the valve assembly back onto the head and replace the O-ring with a new one

- The other side has the same pieces in the opposite order

- Replace the spring, seat, and large seat

- Replace the O-ring with a new one

- Repeat this process on all 3 head assemblies

- Replace the head assembly

- Tighten the assembly skipping bolts in a clockwise pattern to evenly tighten

- Replace the piston sleeve on the 2nd side

- Replace the diaphragm with the beveled side out

- Replace the diaphragm, washer, and nut; tighten with a wrench

- Replace the 2nd head assembly, tightening the bolts with a wrench

- Using non-detergent 40W pump oil; fill the open side of the pump to the brim

- Replace the final piston sleeve, lining up the holes with the piston

- Clean off excess oil Replace the final diaphragm

- Replace the diaphragm, washer, and nut; tighten with a wrench

- Replace the final head

Do you have an instructional video you'd like to see featured? Let us know in the comments below.

Topics: Diaphragm pumps, Sprayer Depot, Instructional Video, Udor Pumps, Udor Kappa, pump repair kit, Sprayer Depot Instructional Video, Diaphragm Kit, repair kit, product highlight, kappa-43

Our Repair Technicians are the best! Yes, we are proud of their excellent service and extensive knowledge in all things sprayers. They are quick to diagnose issues and repair them in no time. They work hard five days a week to make sure your downtime is minimal. Usually, repairs are done within the same day unless we need to order parts or if we have a long queue for the day. Even then, most repairs only take 24-48 hours.

If you've visited our website or follow us in social media then you know we have many instructional videos available. For all of our customers who are not local thus unable to stop by for a repair, we thought it would be cool to have short, easy and convenient videos featuring some of the most common repairs that you can do right at home.

Today we are featuring steps on how to repair a Udor Kappa-40 Diaphragm pump. Watch the video and follow the easy steps outlined below.

For this project you will need the following tools:

- A screwdriver

- Wrench

- Half inch socket

- 11/16" socket

- Diaphragm kit (2 diaphragms, 2 sets of O-rings and an air accumulator diaphragm)

Let's get started! Follow these steps:

- Loosen the bolts in one of the two head assemblies to remove it

- Remove the diaphragm nut and washer using the wrench

- Remove the diaphragm

- Remove the piston sleeve

- Drain the internal oil

- Loosen the bolts on the second head to remove it

- Perform steps 2-5 for the second head

- Clean both sides of the pump with break cleaner

- Place the piston sleeve back in place in one of the two heads

- Place the diaphragm inside. The diaphragm has a beveled side which needs to be facing up

- Use the wrench to tighten the nut and washer back into place

- On each of the two head assemblies remove the inside valve assemble

- Replace the spring, valve seat (beveled side down), and large metal seat

- Replace O-ring with a new one

- The other valve assembly has the exact same parts but reversed (follow steps 13-14)

- Switch to the other head and perform steps 13-15 for this side as well

- Place the head assembly back in place on the side where you replaced the piston sleeve (step 9)

- Tighten bolts in a clockwise pattern to tighten evenly

- Switch to the other head and use non-detergent 40 weight pump oil to fill that open side

- Place piston sleeve back in place

- Clean up any excess oil

- Replace diaphragm, making sure that beveled side is facing up just like in step 13

- Use the wrench to tighten the nut and washer

- Place the head assembly back in place and tighten screws in clockwise pattern to tighten evenly

- There is a clear bolt on the side of the pump and the oil level should be visible right in the center

- Remove the air accumulator head by loosening the bolts

- Once opened, remove the air accumulator diaphragm and replace with new

- Close everything back and tighten for a secure fitting

Topics: Diaphragm pumps, Sprayer Depot, Instructional Video, Udor Pumps, Udor Kappa, pump repair kit, Sprayer Depot Instructional Video, Diaphragm Kit, repair kit

.png?width=280&name=SameDayShippingGuarantee-New%20(1).png)